Organic Materials Laboratory

The Organic Materials Laboratory (UMOC) is part of the Organic and Metallic Materials Unit of the Materials Department of LNEC.

This laboratory, which was established in 1994, has been focused on the characterization of paints, varnishes, organic coatings, powder coatings, and products for horizontal road marking, and had the former designation of LETIV. In 1998, its accreditation domain was extended to the area of bituminous binders and began to be known as LEMOC.

UMOC performs accredited tests and holds Certificate No. L0457.

Additional information can be found in this laboratory's flyer.

Activity areas

UMOC performs laboratory tests for characterization and performance evaluation of the following materials:

- Paints and varnishes;

- Organic coatings and polymeric materials for coating;

- Bituminous binders (bitumens, bituminous emulsions and modified bitumens).

UMROC also performs tests to support the characterization of materials and organic products used in many areas of Civil Engineering, in particular, adjuvants for concrete, adhesives, water-sealing coatings from synthetic binders, and bituminous coatings for waterproofing.

Testing

UMOC carries out, among others, the following laboratory tests, according to EN, ISO and NP standards, or following internal procedures:

Paints and varnishes

- Density and viscosity;

- Non-volatile matter content, pigments and filler content, ash content, solid content by volume and COVs content;

- Hiding power, mud-cracking and drying time;

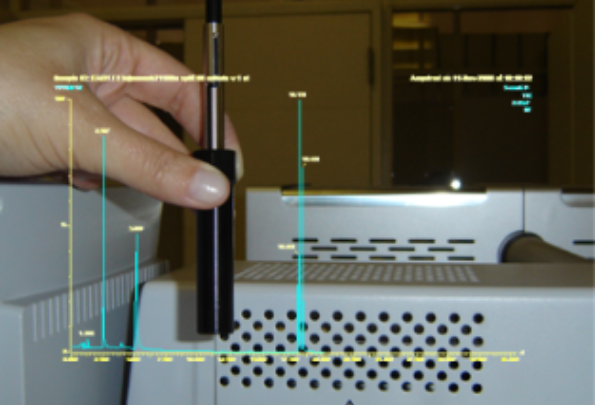

- Binder identification by infrared spectroscopy.

Organic coatings

- Film thickness, hardness, colour, colour difference, gloss, adhesion and flexibility;

- Resistance to impact, to abrasion, cupping test, wash resistance, tensile strength and crack-bridging properties;

- Permeability to water, water vapour, carbon dioxide and chloride ion;

- Resistance to humidity, to humid atmospheres containing sulphur dioxide, to acetic and neutral salt spray and to several liquids;

- Resistance to natural and artificial accelerated ageing (QUV and Xenon chambers).

Powder coatings and lacquered steel and aluminium

- Corrosion resistance (Machu);

- Boiling water resistance;

- Mortar resistance.

Products for horizontal road marking

- Retro-reflection and luminance coefficients and luminance factor;

- Skid resistance;

- Binder and titanium dioxide contents.

Bituminous binders

- Needle penetration, softening point, viscosity, Fraass breaking point, flash point and storage stability;

- Density, solubility and ash content;

- Ductility, cohesion energy and elastic recovery;

- Ageing resistance under the effect of heat, air and pressure (RTFOT, TFOT, PAV);

- Binder and oil distillate content, residual binder after distillation, breaking value, residue on sieving, efflux time, settling tendency (bituminous emulsions).

Other services

UMOC also performs tests and makes applications of products on suitable substrates, in support of the following activities:

- CE marking of construction products in its area of activity;

- European quality marks Qualicoat, Qualideco, and Qualisteelcoat;

- Research projects;

- Advice and technical expertise;

- Quality assessment of new materials and/or field of application.