Ceramic Products Laboratory

|

||

|

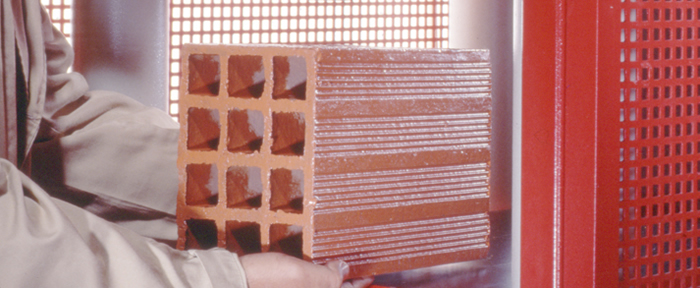

The Ceramic Products Laboratory is integrated in the Concrete, Stone and Ceramics Unit (NBPC) of LNEC’s Department of Materials. With the integration of the Ceramics Division in NBPC in 2013 the Ceramic Products Laboratory (UPC) was created, the latter having maintained the activities developed in the former Division. These activities have been carried out since the creation of LNEC, always with the aim of the construction sector, as regards research, technological development and innovation in the field of civil engineering. Additional information can be found at this laboratory's flyer. Field of expertiseUPC develops laboratory or in situ activity related with the characterization, performance and evaluation of various types of building materials, such as bricks, tiles, concrete block masonry, concrete blocks and slabs for paving, curbs, ceramic tiles, hydraulic mosaics, adhesives for coatings and ornamental stones. This activity consists, apart from laboratory characterization, of carrying out in situ works such as core drilling, non-destructive testing, inspection of structures and other actions that support the issuing of expert reports, the creation of guidelines and the monitoring of the quality control. TestingUPC carries out the following laboratory tests, among others: Bricks / Concrete masonry blocks

Tiles

Concrete block paving

Curbs

Concrete paving slabs

Ornamental stone

Wall and floor tiles

Other servicesIn addition to the laboratory characterization tests referred to above as direct support to the construction sector, UPC develops its activity in other areas such as:

|